Neighbor's Water Heater Automation (part 1)

The Setting

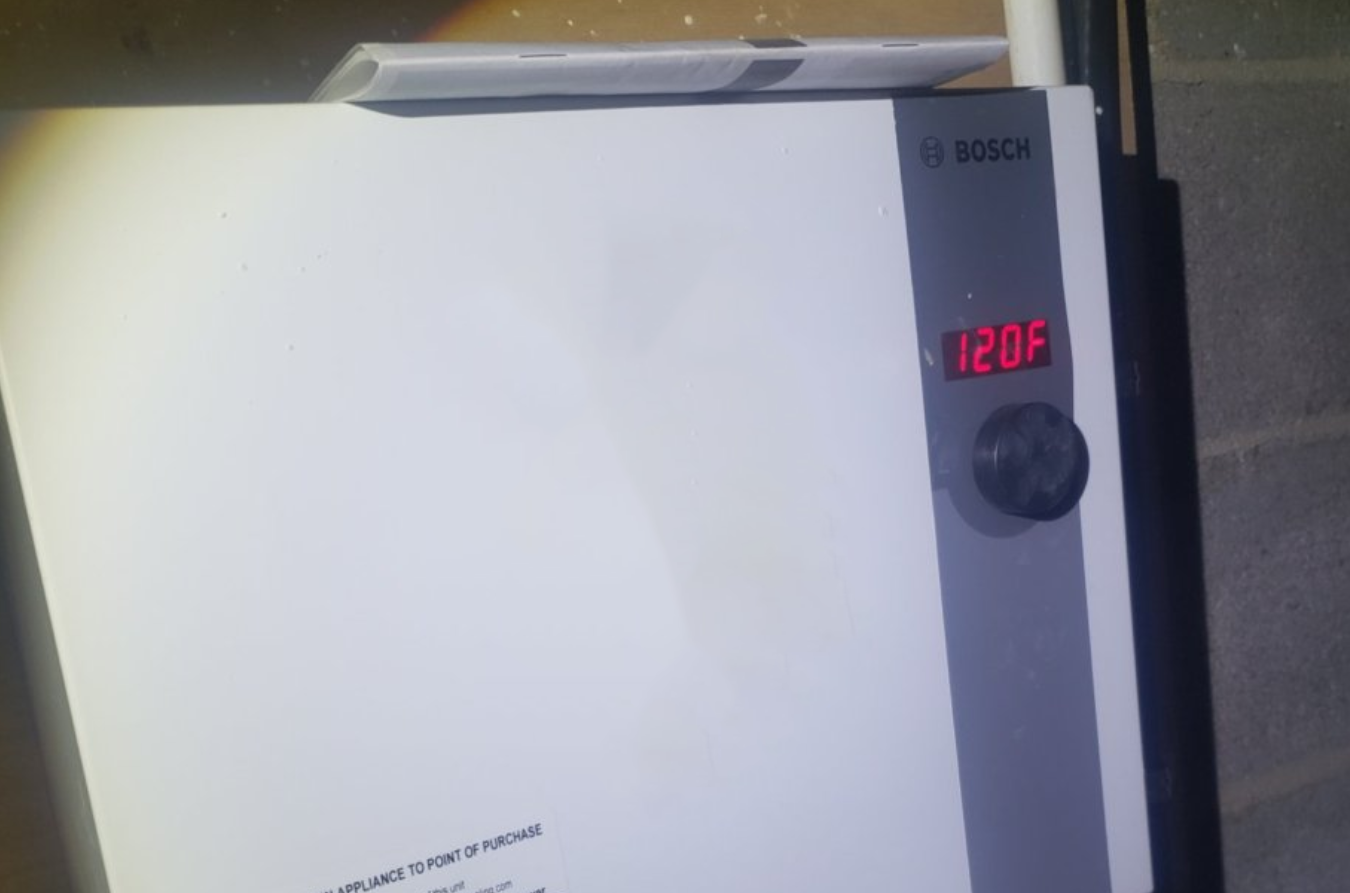

My neighbor has a Bosch tankless water heater he put in last year. This water heater has one slight problem that when the power even blips a single second, it gets set back to its lowest temperature of 95°F. My neighbor (we'll call him Frank for this post because Frank Tank is funny) Frank wants to set his heater to 120°F in his house. The problem arises in that his water heater is under the house in his crawl space.

Without an easy way to set his temperature, he needs to crawl under his crawl space and turn a dial EVERY. SINGLE. TIME.

He asked me if I knew of anything off the shelf that would help. I did not. So I said the only logical thing someone like me would have done. "I can totally automate that!"

The Lay Of The Land

He has a Bosch Tronic 6000C, with what appears to be a rotary encoder knob to set the temperature. I only spent a few minutes under his house while planning this and didn't think to any measuring of how many detents to rotate, or how long the dial took to rotate to 120°F, so my first pass of this project is done with estimations.

Project Time - Round 1!

I have a few random servos laying around, and an NodeMCU ESP8266 module. I figure these would be the perfect solution! ... note: was half right...

I found some code online by Kumar Aditya that is for the two items in my current parts list (ESP8266 and SG90)

The Original code runs a web server on port 80, and runs a web page with some jQuery (wow it's been a while) to change the angle of the servo. I realized this wasn't what I needed because my servos could only go 180° and I might need to go multiple rotations. I found a youtube video on how to make a SG90 run infinite in either direction, so I did those modifications. I then modified the front end code a little bit.

The new code on the back end was actually exactly the same, even though the effect was slightly different. It would run on port 80, listen at / and /angle, but the angle here was more of direction and speed (a vector?). The way the servo was built, 160° was "Stop", higher than that was …